3D AI TIRE INSPECTION SYSTEM

Prevent marking errors and surface anomalies.

The system performs a full sidewall inspection, including lettering, logos, and special characters, ensuring compliance with design and Department of Transportation (DOT) legal requirements.

Doing this verification right on the first cured tire assures that the mold design, the curing process and the markings are in accordance with the specifications. and quickly qualifies the press for further production.

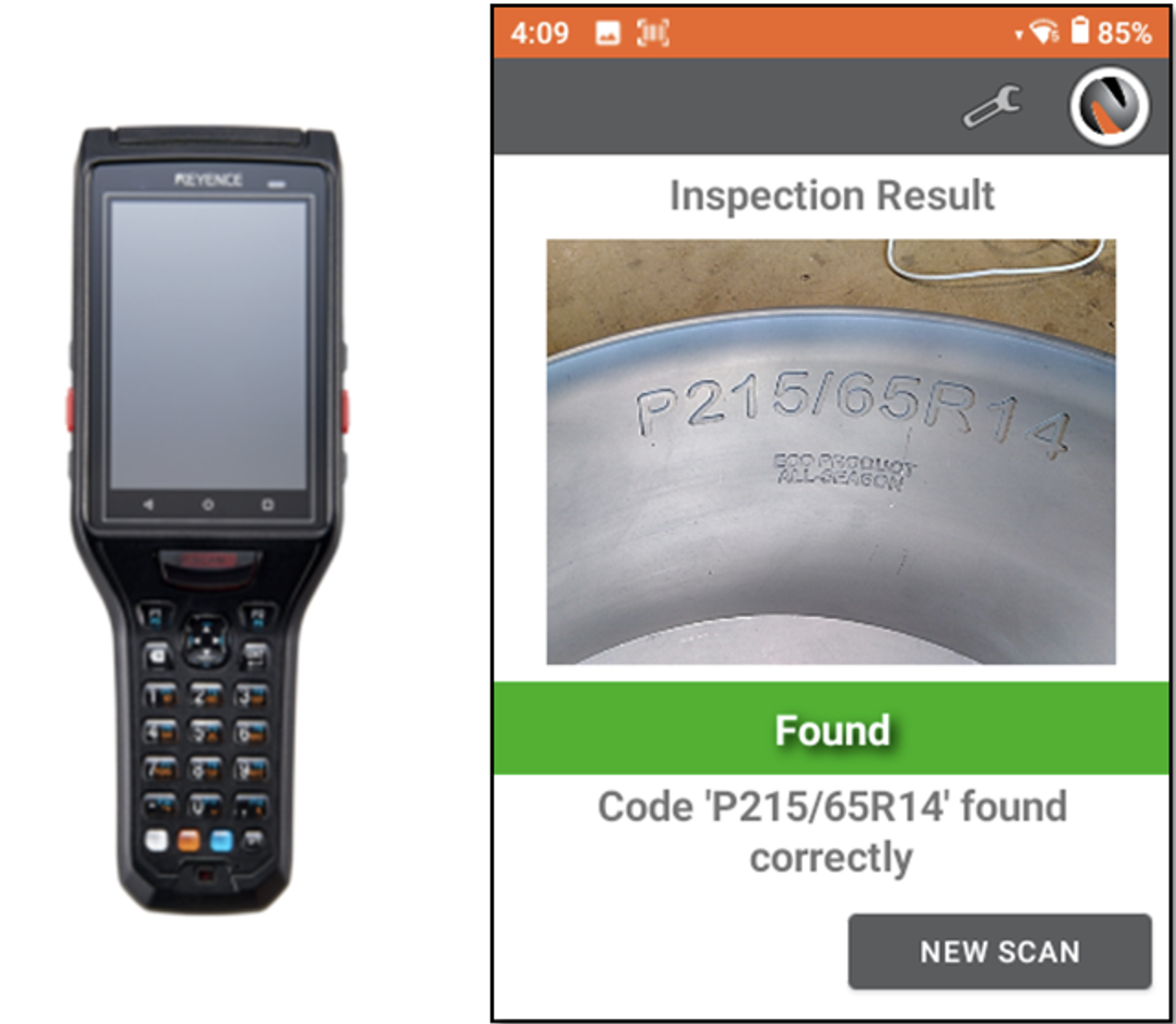

The system combines our 3D scanning technology with artificial intelligence that provides the most reliable optical character reading and verification (OCR and OCV).

Also available with full enclosure and tire lifter.