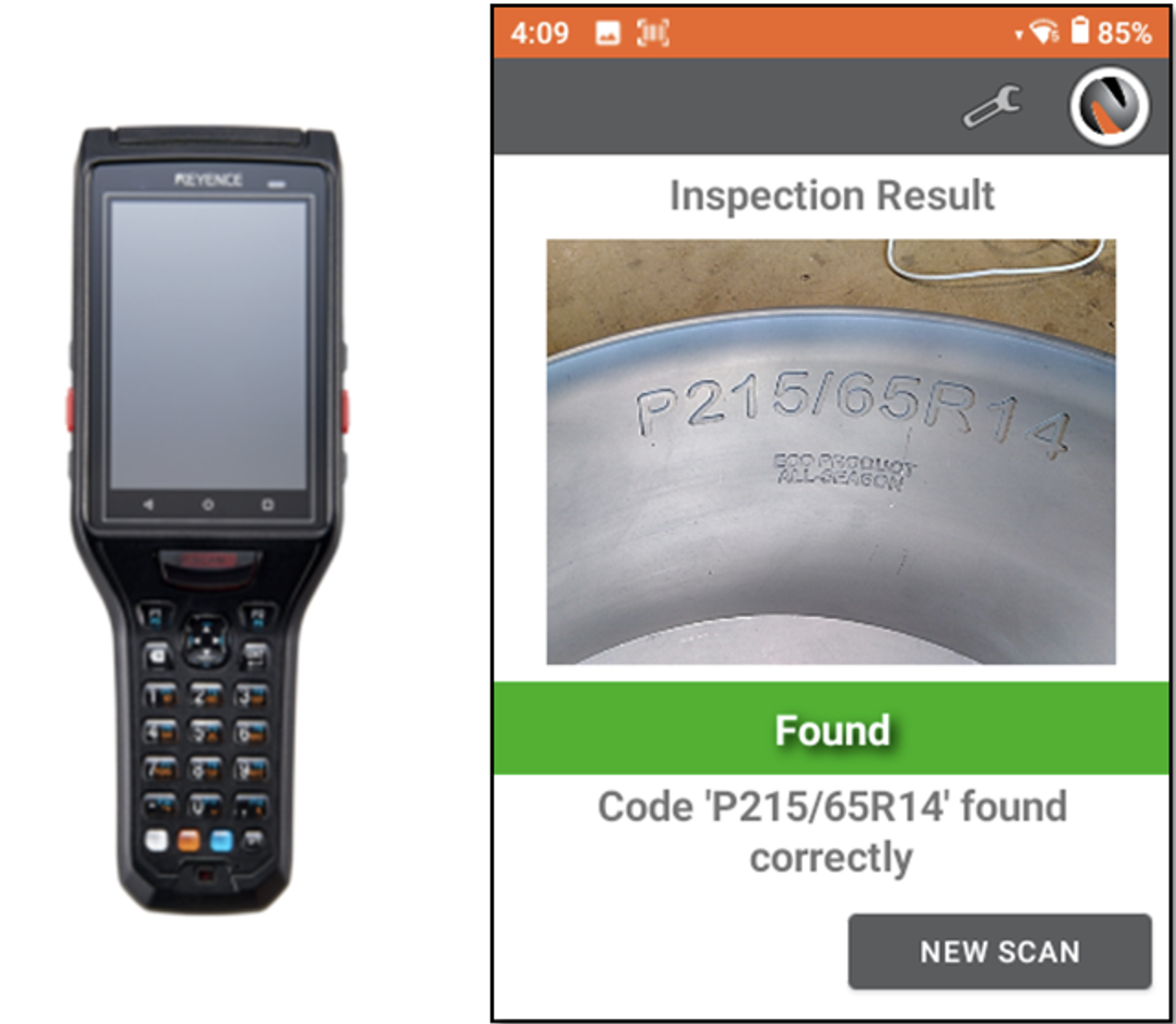

Tire industry applications

3D AI Tire Inspection System

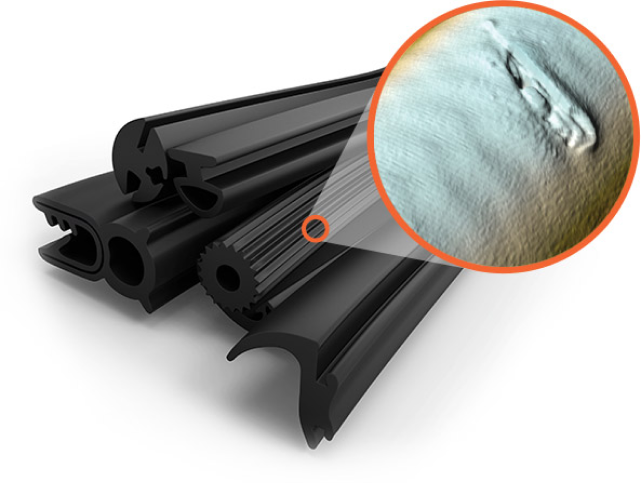

Prevent marking errors and surface anomalies.

The system ensures that all markings molded on the tire, such as logos, symbols, text and characters, match the reference specifications. The system can also be used for production sampling inspection, thus ensuring that mold wear is detected early.